In today’s world, air quality is a growing concern, and understanding the implications of carbon monoxide (CO) levels is crucial. Carbon monoxide, a colorless and odorless gas, can be deadly at high concentrations. Measuring CO levels in parts per million (ppm) helps determine the safety of an environment, with 0 ppm being the ideal reading indicating no presence of this hazardous gas.

Carbon Monoxide 0 PPM

Carbon monoxide levels are measured in parts per million (ppm), and 0 ppm represents no detectable presence, which is ideal for safety. In residential settings, maintaining 0 ppm ensures no exposure to this dangerous gas, protecting occupants from potential harm. Homes and buildings equipped with fuel-burning appliances should regularly monitor CO levels to avoid accumulation.

Detectable levels above 0 ppm indicate CO presence and potential risk. Health symptoms such as headaches and dizziness occur even at low exposure, typically around 30 ppm. Prolonged exposure at higher levels like 70 ppm or above can result in significant health crises. For reference, the Occupational Safety and Health Administration (OSHA) sets permissible exposure limits at 50 ppm over eight hours, underscoring the necessity to aim for 0 ppm in residential environments.

Carbon monoxide originates from incomplete combustion of fuels like gasoline and natural gas. Regular maintenance of appliances, proper ventilation, and installing CO detectors contribute to maintaining safe, optimal levels.

Why 0 PPM Matters

Health Implications

Exposure to CO can cause significant health problems. Even low levels, such as 30 ppm, can result in symptoms like headaches and dizziness. Higher concentrations, over 70 ppm, may cause severe health issues, including impaired vision and reduced cognitive functions. Prolonged exposure increases the risk of long-term damage. Striving for 0 ppm minimizes these health risks, promoting a safer living environment.

Safety Standards

Various organizations set safety standards to mitigate CO hazards. The Occupational Safety and Health Administration (OSHA) specifies a permissible exposure limit of 50 ppm over an eight-hour period. However, for residential areas, aiming for 0 ppm is ideal to prevent any potential exposure. Monitoring devices should be installed and maintained in places like homes and businesses to ensure compliance with these standards and safeguard occupants.

Technology for Detecting 0 PPM

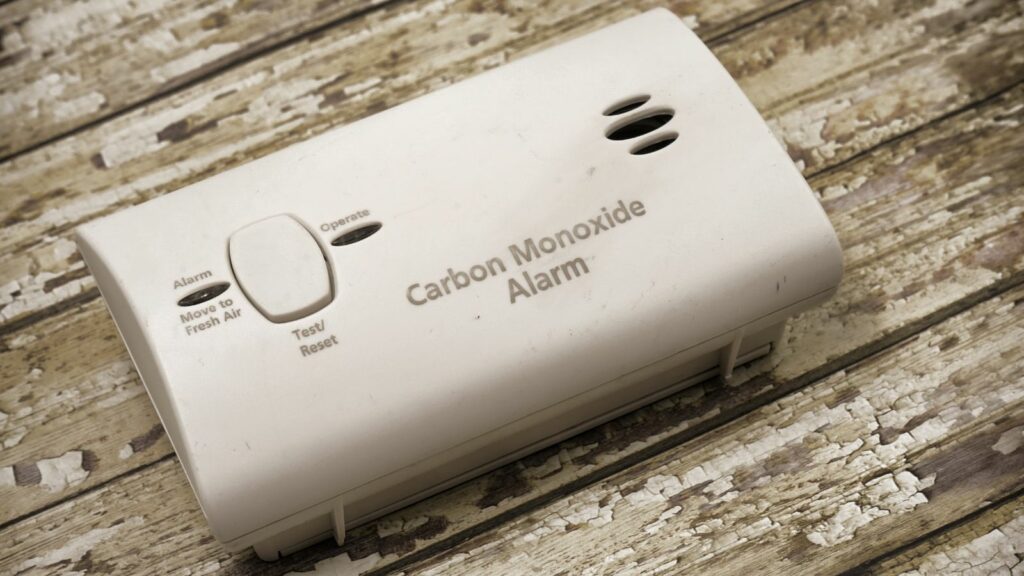

Types of Detectors

Various types of detectors help in accurately measuring CO levels. Electrochemical Sensors use chemical reactions to sense CO, providing precise readings, making them popular for residential use. Metal Oxide Semiconductor detectors measure changes in electrical resistance caused by CO interaction, suitable for broader range detection but typically less accurate than electrochemical sensors. Biomimetic Sensors contain a gel that mimics hemoglobin’s response to CO, changing color when exposed, which is useful in long-term monitoring. Each type is selected based on the user’s needs and the specific environment.

Accuracy and Reliability

Ensuring detector accuracy and reliability is essential for safety. Regular calibration of detectors guarantees consistent performance and accurate readings. Many detectors also feature self-check mechanisms to verify functionality and alert users to malfunctions. High-quality detectors provide readings with minimal deviation, typically within 2-5 ppm of tolerance, significantly contributing to maintaining safe environmental conditions.

Practical Applications

Residential Safety

In homes, achieving carbon monoxide 0 ppm prevents potential health risks from gas-burning appliances like stoves and heaters. Regular maintenance and installation of high-quality CO detectors enhance safety. Detectors alert occupants to any rise in CO, allowing immediate actions to address sources. Ventilation systems and adherence to guidelines for appliance use further support these efforts, keeping living spaces safe and secure.

Industrial Settings

Industries prioritize maintaining carbon monoxide 0 ppm to protect workers from exposure risks. Processes involving combustion, such as those in manufacturing or chemical plants, need constant monitoring. Advanced sensor systems ensure accurate readings and immediate detection of any CO presence. Proper ventilation and employee training complement these systems, ensuring adherence to safety standards and promoting a healthy workplace environment.

Prioritizing Quality

Achieving and maintaining carbon monoxide 0 ppm is essential for ensuring a safe and healthy environment. With the increasing awareness of CO dangers, it’s vital for homeowners, businesses, and policymakers to prioritize air quality.